The Grand Challenge:

“The deepest and most important unsolved problem in condensed matter science is probably the theory of the nature of glass and the glass transition!”

------ P.W. Anderson [Science 267, 1616 (1995)]

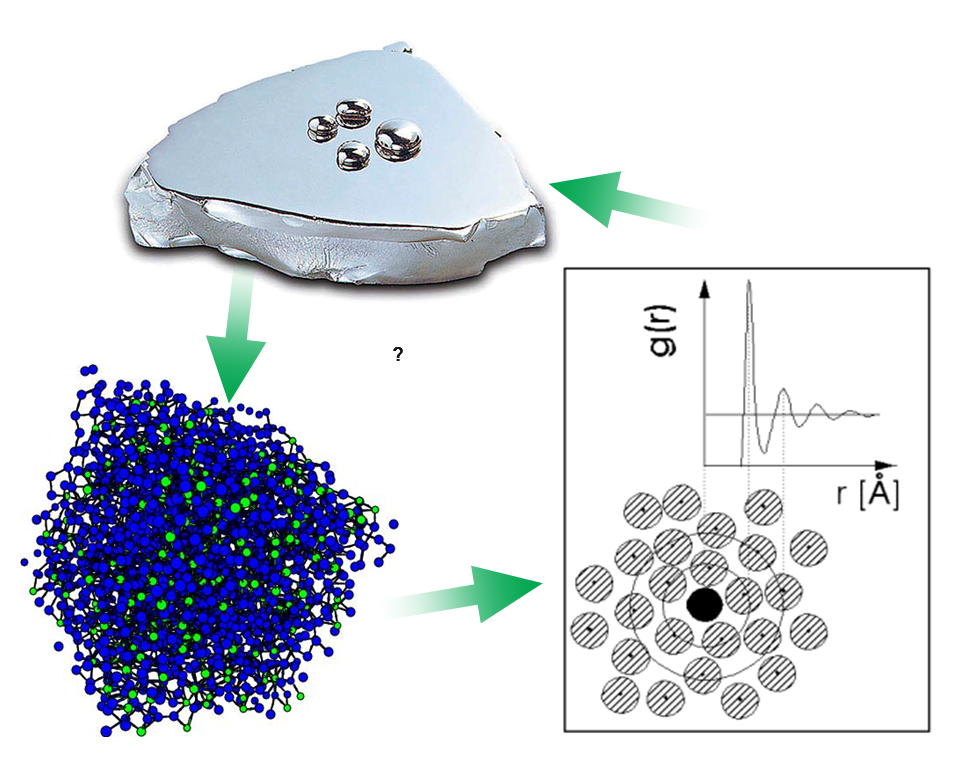

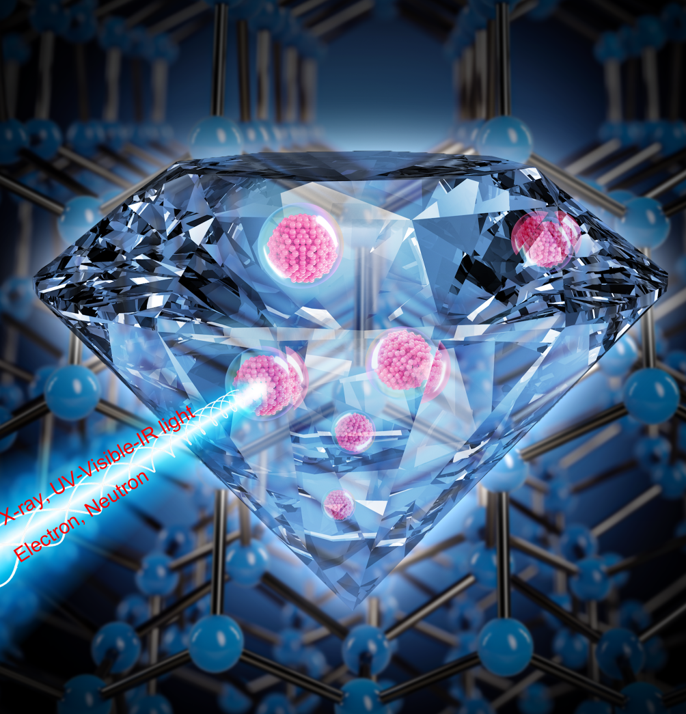

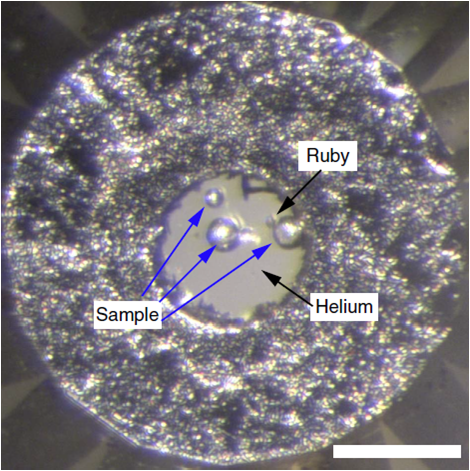

The Amorphous Materials Group aims to address the grand challenges in the field of amorphous materials (including the structure of glass, the nature of glass transition, the heterogeneity of glass, polyamorphism, the structure-properties relationship of glass and etc.) by using state-of-the-art in situ high pressure and high temperature synchrotron radiation x-ray diffraction, imaging and spectroscopy techniques combined with simulation. AMAT group is also interested in developing new techniques which are dedicated to amorphous materials particularly under high pressure and high temperature.

OUR MOTTO:

DON’T LIMIT YOUR CHALLENGES! CHALLENGE YOUR LIMITS!

Dec 30, 2023 — A research team led by Drs. Qiaoshi Zeng and Ho-kwang Mao from Center for High Pressure Science and Technology Advanced Research (HPSTAR) repeatedly reproduced the near-room temperature resistance transition in the reaction products (Lu-H-N) of Lu with hydrogen-nitrogen mixture by employing in-situ high-pressure four-probe electrical transport measurement technique to monitor the entire reaction process under different conditions (pressure, temperature, and time). With this reliable experimental protocol, they explicitly reveal that the near-room temperature resistance transition in the Lu-H-N did not result in zero resistance, nor did it exhibit magnetic suppression, ruling out the possibility of any superconductivity. Instead, the resistance transition is suggested to be related to an order-to-disorder transition of hydrogen octahedral vacancies in non-stoichiometric lutetium hydrides, which leads to a metal-to-semiconductor/insulator transition with drastic resistance change. This study overturns the sensational "near-room temperature superconductivity" phenomenon in the Lu-H-N system. The related findings, titled "Origin of the near-room temperature resistance transition in lutetium with H2/N2 gas mixture under high pressure," were published in a recent issue of the National Science Review. (--more)

Dec 30, 2023 — A research team led by Drs. Qiaoshi Zeng and Ho-kwang Mao from Center for High Pressure Science and Technology Advanced Research (HPSTAR) repeatedly reproduced the near-room temperature resistance transition in the reaction products (Lu-H-N) of Lu with hydrogen-nitrogen mixture by employing in-situ high-pressure four-probe electrical transport measurement technique to monitor the entire reaction process under different conditions (pressure, temperature, and time). With this reliable experimental protocol, they explicitly reveal that the near-room temperature resistance transition in the Lu-H-N did not result in zero resistance, nor did it exhibit magnetic suppression, ruling out the possibility of any superconductivity. Instead, the resistance transition is suggested to be related to an order-to-disorder transition of hydrogen octahedral vacancies in non-stoichiometric lutetium hydrides, which leads to a metal-to-semiconductor/insulator transition with drastic resistance change. This study overturns the sensational "near-room temperature superconductivity" phenomenon in the Lu-H-N system. The related findings, titled "Origin of the near-room temperature resistance transition in lutetium with H2/N2 gas mixture under high pressure," were published in a recent issue of the National Science Review. (--more)

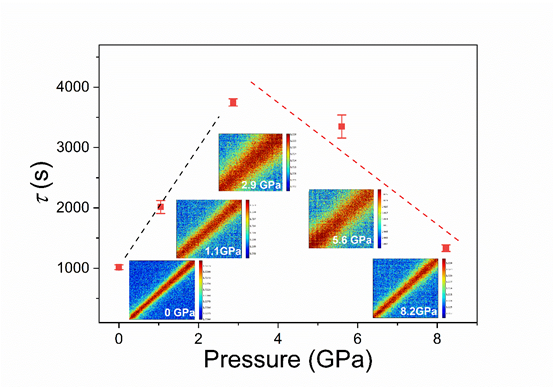

Accelerated relaxation dynamics in compressed cerium-based metallic glass

June 5, 2023 — A major stumbling block in our understanding of glass and glass phenomena is the elusive relationship between relaxation dynamics and glass structure. A team led by Dr. Qiaoshi Zeng from HPSTAR recently developed a new in situ high-pressure wide-angle x-ray photon correlation spectroscopy method to enable atomic-scale relaxation dynamics studies in metallic glass systems under extreme pressures. The study is published in the latest Proceedings of the National Academy of Sciences (PNAS) edition. (--more)

June 5, 2023 — A major stumbling block in our understanding of glass and glass phenomena is the elusive relationship between relaxation dynamics and glass structure. A team led by Dr. Qiaoshi Zeng from HPSTAR recently developed a new in situ high-pressure wide-angle x-ray photon correlation spectroscopy method to enable atomic-scale relaxation dynamics studies in metallic glass systems under extreme pressures. The study is published in the latest Proceedings of the National Academy of Sciences (PNAS) edition. (--more)

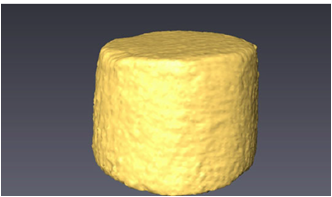

Capturing high pressures in diamond capsules - Drs. Zhidan Zeng and Charles Zeng

AUGUST 17, 2022 — Preservation of the high-pressure states of materials at ambient conditions is a long-sought-after goal for fundamental research and practical applications. A team of scientists led by Drs. Zhidan (Denise) Zeng, Qiaoshi Zeng, and Ho-Kwang Mao from the Center for High Pressure Science and Technology Advanced Research (HPSTAR) and Prof. Wendy Mao from Stanford University report an innovative breakthrough where they were able to maintain the extraordinary properties of high-pressure materials in free-standing, nanostructured diamond capsules without the support of traditional bulky pressure vessels. Their work was recently published in Nature.(https://www.nature.com/articles/s41586-022-04955-z) --more

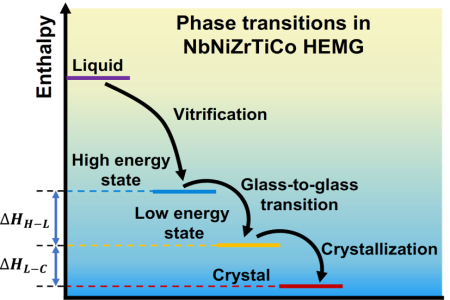

High entropy: another dimension for glass states exploration and glassy properties tuning - Dr. Zeng

APRIL 26, 2022 New study from a team of scientists co-led by Dr. Qiaoshi Zeng from Center for High Pressure Science and Technology Advance Research reported a high-entropy-induced glass-to-glass transition in the NbNiZrTiCo high-entropy metallic glass. This glass-to-glass transition leads to a significant improvement of the modulus, hardness, and thermal stability. Their findings demonstrate that high configurational entropy could be a new dimension for tuning the glass states and properties in multi-component amorphous alloys. This work has recently been published in Nature Communications (DOI: doi.org/10.1038/s41467-022-29789-1). (-- more)

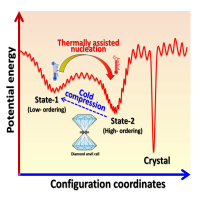

Two-way tuning of structural order in metallic glasses - Dr. Qiaoshi Zeng

JUN. 16, 2020—Metallic glasses (MGs) are disordered alloys with many properties superior to conventional crystalline metals. Unlike crystalline materials that follow strict atomic-packing rules and imposed symmetry, in principle, metallic glasses have a high degree of freedom to arrange their atoms with almost infinite possibilities in their configuration space. However, in practice, effectively modulating the disordered structures of metallic glasses is rather challenging. A new study from a team of scientists led by Dr. Qiaoshi Zeng from HPSTAR realized a two-way tuning of structures between distinct states in metallic glasses by combining temperature and pressure. The results are published in the Jan. 16th issue of Nature Communications (DOI: 10.1038/s41467-019-14129-7). --more.

JUN. 16, 2020—Metallic glasses (MGs) are disordered alloys with many properties superior to conventional crystalline metals. Unlike crystalline materials that follow strict atomic-packing rules and imposed symmetry, in principle, metallic glasses have a high degree of freedom to arrange their atoms with almost infinite possibilities in their configuration space. However, in practice, effectively modulating the disordered structures of metallic glasses is rather challenging. A new study from a team of scientists led by Dr. Qiaoshi Zeng from HPSTAR realized a two-way tuning of structures between distinct states in metallic glasses by combining temperature and pressure. The results are published in the Jan. 16th issue of Nature Communications (DOI: 10.1038/s41467-019-14129-7). --more.

High-Entropy Alloy: changing faces under high pressure - Dr. Qiaoshi Zeng

JUNE 2, 2017—A new study co-led by a HPSTAR staff scientist, Dr. Qiaoshi “Charles” Zeng revealed irreversible polymorphic phase transitions between the fcc and hcp structures in a prototype high-entropy alloy CoCrFeMnNi using in situ high pressure and high temperature x-xay diffraction techniques. Their discovery was just published in Nature Communications (DOI:10.1038/ncomms15687) on June 1st. These results shed new light on the thermodynamics and kinetics of complex HEA systems and also opens a new avenue towards tuning HEAs’ properties via polymorphic structural transitions for applications. --more

JUNE 2, 2017—A new study co-led by a HPSTAR staff scientist, Dr. Qiaoshi “Charles” Zeng revealed irreversible polymorphic phase transitions between the fcc and hcp structures in a prototype high-entropy alloy CoCrFeMnNi using in situ high pressure and high temperature x-xay diffraction techniques. Their discovery was just published in Nature Communications (DOI:10.1038/ncomms15687) on June 1st. These results shed new light on the thermodynamics and kinetics of complex HEA systems and also opens a new avenue towards tuning HEAs’ properties via polymorphic structural transitions for applications. --more

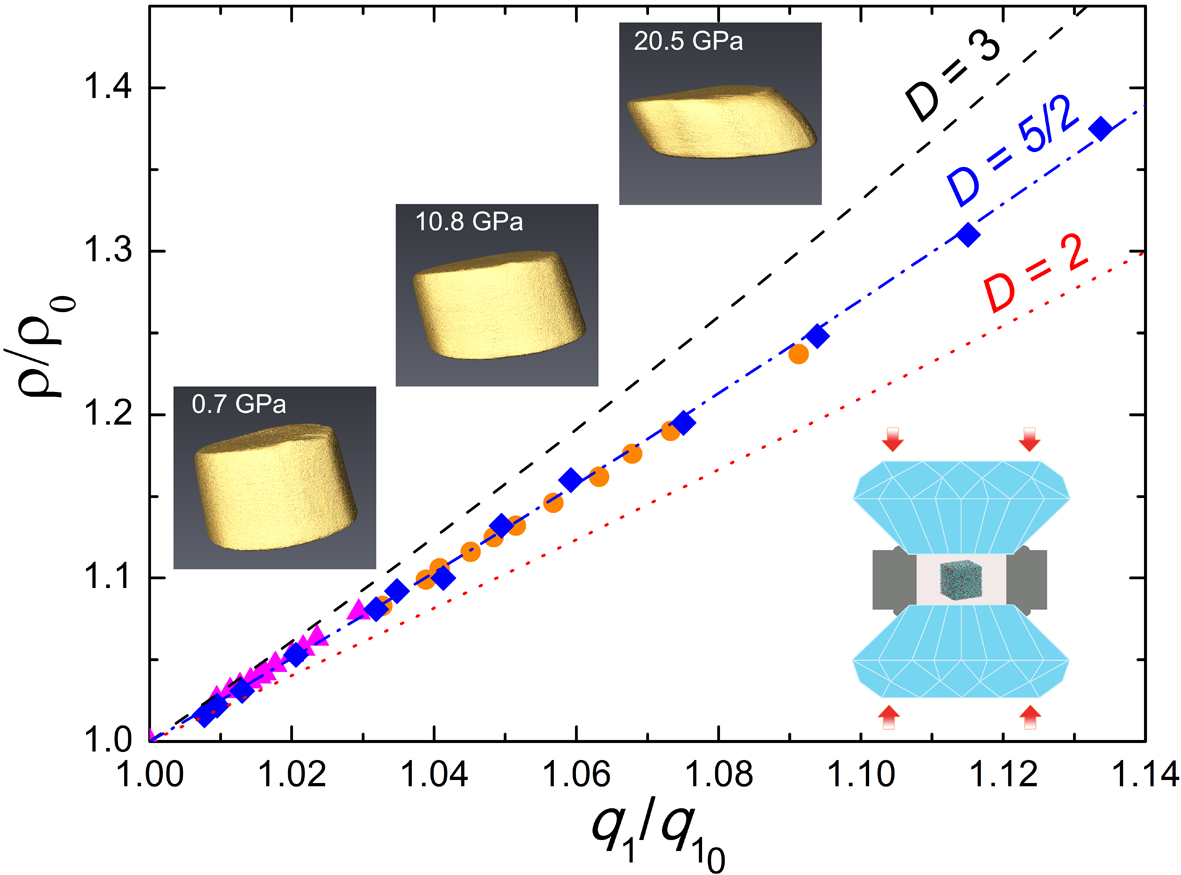

A general structural-property relationship in metallic glass - Charles Zeng

Shanghai February 01, 2016 — Structure-property relationship is a central topic in materials science. In crystalline materials, the well-defined lattice structure or defects enable us to describe their properties quantitatively. The structure of glass is basically featureless, very few rigorous laws are currently known for defining its ‘disordered’ structure. Establishing general and exact rules regarding structure-property relationships in glass remain elusive. A breakthrough has been made by a international team led by Dr. Qiaoshi Zeng, a staff scientist from HPSTAR. This team established a general rule correlating the bulk properties (volume V) with most prominent atomic structure information (principle diffraction peak position q1) for metallic glasses, i.e. V∝(1/q1)2.5. It is shown that the 2.5 power law is strictly followed by any metallic glass with its volume tuned by pressure and/or composition. This general 2.5 power law is attributed to the well constrained structure change/modification inevitably happened during pressure and/or composition tuning of metallic glasses, which brings new insight into the structure of metallic glasses. These results are just published by PNAS. --more

Shanghai February 01, 2016 — Structure-property relationship is a central topic in materials science. In crystalline materials, the well-defined lattice structure or defects enable us to describe their properties quantitatively. The structure of glass is basically featureless, very few rigorous laws are currently known for defining its ‘disordered’ structure. Establishing general and exact rules regarding structure-property relationships in glass remain elusive. A breakthrough has been made by a international team led by Dr. Qiaoshi Zeng, a staff scientist from HPSTAR. This team established a general rule correlating the bulk properties (volume V) with most prominent atomic structure information (principle diffraction peak position q1) for metallic glasses, i.e. V∝(1/q1)2.5. It is shown that the 2.5 power law is strictly followed by any metallic glass with its volume tuned by pressure and/or composition. This general 2.5 power law is attributed to the well constrained structure change/modification inevitably happened during pressure and/or composition tuning of metallic glasses, which brings new insight into the structure of metallic glasses. These results are just published by PNAS. --more

Metallic glass: homogenous in appearance, fractal at heart - Dr. Qiaoshi Zeng & Dr. Wendy Mao

Shanghai September 18th, 2015 — The atomic structure of glasses has been a long-standing unsolved mystery in condensed mater physics and materials science. A breakthrough in understanding the atomic structure of an important new category of glass — metallic glasses was made by a joint research team including staff scientists of HPSTAR, Dr. Qiaoshi Zeng and Dr. Wendy L. Mao. From multiple techniques, the team found that a specific fractal model — the percolation cluster packing could provide a perfect explanation of the 2.5 power law observed in the compression experiments of metallic glasses and a unified description of the atomic structure of metallic glasses from short range to macroscopic length scale for the first time. These results are just published by Science (DOI: 10.1126/science.aab1233). --more

Shanghai September 18th, 2015 — The atomic structure of glasses has been a long-standing unsolved mystery in condensed mater physics and materials science. A breakthrough in understanding the atomic structure of an important new category of glass — metallic glasses was made by a joint research team including staff scientists of HPSTAR, Dr. Qiaoshi Zeng and Dr. Wendy L. Mao. From multiple techniques, the team found that a specific fractal model — the percolation cluster packing could provide a perfect explanation of the 2.5 power law observed in the compression experiments of metallic glasses and a unified description of the atomic structure of metallic glasses from short range to macroscopic length scale for the first time. These results are just published by Science (DOI: 10.1126/science.aab1233). --more

A universal fractional noncubic power law for density in metallic glasses - Dr. Qiaoshi Zeng Tuning with pressure, a research team led by Dr. Qiaoshi Zeng with collaborators from HPSTAR, Stanford University, SLAC National Accelerator Laboratory, and Geophysical Laboratory at Carnegie Institution of Washington made a surprising discovery that the three-dimensional density of metallic glasses is not simply the cube of their one-dimensional average interatomic spacing, but varies with a universal 5/2 fractional power. The result is published by Phys. Rev. Lett. on May 8, 2014. --more

Tuning with pressure, a research team led by Dr. Qiaoshi Zeng with collaborators from HPSTAR, Stanford University, SLAC National Accelerator Laboratory, and Geophysical Laboratory at Carnegie Institution of Washington made a surprising discovery that the three-dimensional density of metallic glasses is not simply the cube of their one-dimensional average interatomic spacing, but varies with a universal 5/2 fractional power. The result is published by Phys. Rev. Lett. on May 8, 2014. --more

PI:

Dr. Qiaoshi(Charles) Zeng

Dr. Qiaoshi(Charles) Zeng

Selected publications:

30. Xin Zhang ,† Hongbo Lou,† Beatrice Ruta,* Yuriy Chushkin, Federico Zontone, Shubing Li, Dazhe Xu, Tao Liang, Zhidan Zeng, Ho-kwang Mao,* Q.S. Zeng,* Pressure-induced nonmonotonic cross-over of steady relaxation dynamics in a metallic glass, PNAS, 120, e2302281120 (2023).

26. Xin Zhang, Hongbo Lou, Fei Zhang, Hengwei Luan, Tao Liang, Shubin Li, Xiehang Chen, Yang Shao, Ke-Fu Yao,* Zhidan Zeng, Q.S. Zeng,* Pressure-induced local structural crossover in a high-entropy metallic glass,

24.

Email: zengqs@hpstar.ac.cn

Phone: +86 (21) 8017-7102

"FINDING ORDER IN DISORDER"

"在无序的世界里寻找有序"

We are currently focused on:

1. Atomic structure of metallic glasses

2. Structure/properties tuning under high pressure

3. Disorder-order transition in metallic glasses

4. Polyamorphic transitions in metallic glasses

5. Structural heterogeneity of metallic glasses

6. High pressure and high/low temperature properties of metallic glasses

7. Novel materials synthesis under high pressure and/or high temperature

8. Development of novel techniques dedicated to amorphous materials

Techniques we are mainly using:

1. Materials synthesis techniques:

Arc/induction melting, Suction/injection copper mold casting, Melt spinning.

2. Materials characterization techniques:

2.1 Synchrotron radiation techniques

X-ray diffraction,

Pair distribution function,

X-ray absorption spectroscopy,

X-ray resonant inelastic scattering spectroscopy,

X-ray imaging

X-ray small angle scattering

X-ray photo correlation spectroscopy

X-ray emission spectroscopy

2.2 Microscopic structure characterization

Scanning electron microscopy (SEM)

High resolution electron transmission microscopy (HRTEM)

Atomic force microscopy (AFM)

2.3 Laser Raman spectroscopy

2.4 Electrical and magnetic properties measurement using PPMS

2.5 Mechanical properties testing (tension, compression, micro/nano-indentation),

2.6 Ultrasonic measurement,

2.7 Density measurement,

2.8 Differential scanning calorimetry (DSC)

2.9 Simulation (Reverse Monte Carlo, Molecule Dynamics, etc.)

3. Extreme conditions techniques:

3.1 High pressure (Diamond anvil cell (DAC), Multi-anvil Press, Paris-Edinburgh cell, Dynamic compression in DAC, Four-probe resistance measurement in DAC)

3.2 Low temperature (Cryostat)

3.3 High temperature (Laser heating, Resistive heating)

Major in-house equipment:

More equipment is coming soon......

Complete List (updated on Feb, 2024):

116. Liliang Shao, Rongsheng Bai, Yanxue Wu, Jing Zhou, Xing Tong, Hailong Peng, Tao Liang, Zongzhen Li, Q.S. Zeng, Bo Zhang, Haibo Ke*, Weihua Wang* Critical state-induced emergence of superior magnetic performances in an iron-based amorphous soft magnetic composite, Mater. Futures, 10.1088/2752-5724/ad2ae8 (2024).

115. Dong Wang, Ningning Wang, Caoshun Zhang, Chunsheng Xia, Weicheng Guo, Xia Yin, Kejun Bu, Takeshi Nakagawa, Jianbo Zhang, Federico Gorelli, Philip Dalladay-Simpson, Xujie Lü, Liling Sun, Jinguang Cheng, Q.S. Zeng, Yang Ding* and Ho-kwang Mao, Unveiling a novel metal-to-metal transition in LuH2: Critically challenging superconductivity claims in lutetium hydrides, Matter Radiat. Extremes, 9, 037401 (2024)

114. Di Peng, Q.S. Zeng,* Fujun Lan, Zhenfang Xing, Zhidan Zeng, Xiaoxing Ke, Yang Ding, Ho-kwang Mao*, Origin of the near-room temperature resistance transition in lutetium with H2/N2 gas mixture under high pressure, National Science Review, nwad337 (2023)

113. Di Peng, Q.S. Zeng,* Fujun Lan, Zhenfang Xing, Yang Ding, Ho-kwang Mao,* The near room-temperature upsurge of electrical resistivity in Lu-H-N is not superconductivity, but a metal-to-poor-conductor transition, Matter Radiat. Extremes, 8, 058401 (2023).

112. Xin Zhang ,† Hongbo Lou,† Beatrice Ruta,*Yuriy Chushkin, Federico Zontone, Shubing Li, Dazhe Xu, Tao Liang, Zhidan Zeng, Ho-kwang Mao,* Q.S. Zeng,* Pressure-induced nonmonotonic cross-over of steady relaxation dynamics in a metallic glass, PNAS, 120, e2302281120 (2023).

111. Shuang Ma, Jie Lu, Yanyu Wang, Yanhui Li, Xudong Wang, Q.S. Zeng,* Wei Zhang,* Man Yao,* Role of rare earth elements addition in enhancing glass-forming ability and magnetic softness of a Co75B25 metallic glass: theoretical prediction and experimental verification, J. Mater. Res. Tech., 26, 6193 (2023).

110. Jing Zhou, Xuesong Li, Xibei Hou, Haibo Ke, Xingdu Fan, Junhua Luan, Hailong Peng, Q.S. Zeng, Hongbo Lou, Jianguo Wang, Chain Tsuan Liu, Baolong Shen, Baoan Sun,* Weihua Wang, and Haiyang Bai*, Adv. Mater., 2304490 (22023).

109. Qing Du, Xiong-Jun Liu*, Yihuan Cao, Q.S. Zeng, Hui Wang, Yuan Wu, Suihe Jiang, Xiaobin Zhang and Zhao-Ping Lu*, Sci. China Mater., https://doi.org/10.1007/s40843-023-2507-6 (2023).

108. Minhyuk Park, Qing Yu, Qing Wang, Chaojie Chen, Zhibo Zhang, Ziyin Yang, Huan Chen, Q.S. Zeng, Yunlong Zi, Jun Fan*, Yong Yang*, Ultrastrong yet Ductile 2D Titanium Nanomaterial for On-Skin Conformal Triboelectric Sensing, Nano Lett., 23, 5802 (2023).

107. Qifan Wang, Hongbo Lou, Yoshio Kono, Daijo Ikuta, Zhidan Zeng, Q.S. Zeng,* Viscosity anomaly of a metallic glass-forming liquid under high pressure, J. Non-Cryst. Solids, 615, 122412 (2023).

106. Q.S. Zeng,* In situ high-pressure wide-angle hard x-ray photon correlation spectroscopy: A versatile tool probing atomic dynamics of extreme condition matter, Matter Radiat. Extremes, 8, 028101 (2023).

105. W Hang, C Song, Z Yin, Y Liu, Q Wang, Y Wang, Y Ma,* Q.S. Zeng,* Research on Chemical Mechanical Polishing Technology for Zirconium-Based Amorphous Alloys,Micromachines, 14, 584 (2023).

104. Chen Lin#, Zijun Zhang#, Zhenbang Dai#, Mengjiao Wu, Shi Liu, Jialu Chen, Chenqiang Hua, Yunhao Lu, Fei Zhang, Hongbo Lou, Hongliang Dong, Q.S. Zeng, Jing Ma, Xiaodong Pi, Yongjun Wu, He Tian*, AndrewM. Rappe, Zhaohui Ren*, Gaorong Han*, Solution epitaxy of polarization-gradient ferroelectric oxide films with colossal photovoltaic current, submitted to Nat. Commun., 14, 2341 (2023).

103. Mingjuan Cai, Jingjing Wang, Qianqian Wang, Zhijun Guo, Qiang Luo, Jing Zhou, Tao Liang, Xuesong Li, Q.S. Zeng, Baolong Shen*, Improvement of soft-magnetic properties for high Bs Fe-based amorphous alloys by stress annealing, Mater. Res. Lett.,11, 595 (2023).

102. Alexander Breindel, Yuhang Deng, Camilla M. Moir, Yuankan Fang, Sheng Ran, Hongbo Lou, Shubin Li, Q.S. Zeng, Lei Shu, Christian T. Wolowiec, Ivan K. Schuller, Priscila F. S. Rosa, Zachary Fisk, John Singleton, and M. Brian Maple, Probing FeSi, a d-electron topological Kondo insulator candidate, with magnetic field, pressure, and microwaves, PNAS, 120, e2216367120 (2023).

101. Zhidan Zeng, Jianguo Wen, Hongbo Lou, Xin Zhang, Liuxiang Yang, Lijie Tan, Benyuan Cheng, Xiaobing Zuo, Wenge Yang, Wendy L. Mao,* Ho-kwang Mao,* Q.S. Zeng,* Preservation of high-pressure volatiles in nanostructured diamond capsules, Nature, 608, 513 (2022).

100.Kejun Bu, Qingyang Hu, Xiaohuan Qi, Dong Wang, Songhao Guo, Hui Luo, Tianquan Lin, Xiaofeng Guo, Q.S. Zeng, Yang Ding, Fuqiang Huang, Wenge Yang, Ho-Kwang Mao and Xujie Lü,* Nested order-disorder framework containing a crystalline matrix with self-filled amorphous-like innards, Nat. Commun., 13, 4650 (2022).

99. Hengwei Luan, Xin Zhang, Hongyu Ding, Fei Zhang, J. H. Luan, Z. B. Jiao, Ranbin Wang, Jialun Gu, Chunlin Shao, Yang Shao*, Q.S. Zeng,* Na Chen,* C.T. Liu, Ke-Fu Yao,* High-entropy induced glass-to-glass transition in a metallic glass, Nat. Commun., 13, 2183 (2022).

98. Jingyang Zhang,# Qing Yu,# Qing Wang,# Jia Li, Zhibo Zhang, Tianyu Wang, Shuo Shuang, Qihong Fang,* Q.S. Zeng,* and Yong Yang,* Strong yet Ductile High Entropy Alloy Derived Nanostructured Cermet, Nano Lett., 22, 7370 (2022).

97. Ye Liu, Ziliang Yin, Hongbo Lou,* Tao Liang, Hongliang Dong, Dazhe Xu, Chao Song, Qifan Wang, Songyi Chen, Xin Zhang, Xiehang Chen, Zhidan Zeng, Q.S. Zeng,* The effect of impurities in zirconium on Zr55Cu30Al10Ni5 metallic glass, J. Non-Cryst. Solids, 596, 121878 (2022).

96. Tao Liang, Qing Yu, Ziliang Yin, Songyi Chen, Ye Liu, Yanping Yang, Hongbo Lou, Baolong Shen, Zhidan Zeng, Q.S. Zeng,* Spatial resolution limit for nanoindentation mapping on metallic glasses, Materials, 15, 6319 (2022).

95. Ming Yang, Wenyue Li, Xiongjun Liu,* Hui Wang, Yuan Wu, Xianzhen Wang, Fei Zhang, Q.S. Zeng, Dong Ma, Haihui Ruan, * Zhaoping Lu*, Configurational entropy effects on glass transition in metallic glasses, J. Phys. Chem. Lett., 13, 7889 (2022).

94. Tao Liang, Lianghua Xiong, Hongbo Lou, Fujun Lan, Junran Zhang, Ye Liu, Stella Chariton, Vitali B. Prakapenka, Q.S. Zeng,* Zhidan Zeng,* Mechanical properties and pressure-induced phase transitions of Si-IV, Scripta Mater., 220, 114936 (2022).

93. Xin Zhang, Hengwei Luan, Hongbo Lou, Tao Liang, Songyi Chen, Dazhe Xu, Ziliang Yin, Liang Wang, Jianrong Zeng, Yang Ren, Zhidan Zeng, Yang Shao, Ke-Fu Yao,* Q.S. Zeng,* Highly Variable Chemical Short-Range Order in a High-Entropy Metallic Glass, Mater. Today Phys., 27, 100799 (2022).

92. Q.F. He, J.G. Wang, H.A. Chen, Z.Y. Ding, Z.Q. Zhou, L.H. Xiong, J.M. Pelletie, J.C. Qiao, Q. Wang, L.L. Fan, Y. Ren, Q.S. Zeng, C.T. Liu, C.W. Pao*, D.J. Srolovitz*, Y. Yang,* A highly distorted ultraelastic chemically complex Elinvar alloy, Nature, 602, 251 (2022).

91. Xin Zhang, Hongbo Lou, Fei Zhang, Hengwei Luan, Tao Liang, Shubin Li, Xiehang Chen, Yang Shao, Ke-Fu Yao,* Zhidan Zeng, Q.S. Zeng,* Pressure-induced local structural crossover in a high-entropy metallic glass,Phys. Rev. B, 105, 224201 (2022).

90. Songyi Chen, Dazhe Xu, Xin Zhang, Xiehang Chen, Ye Liu, Tao Liang, Ziliang Yin, Sheng Jiang, Ke Yang, Jianrong Zeng, Hongbo Lou, Zhidan Zeng, Q.S. Zeng,* Reversible linear compression behavior of free volume in a metallic glass, Phys. Rev. B, 105, 144201 (2022).

89. Qing Yu, Jingyang Zhang, Jia Li, Tianyu Wang, Minhyuk Park, Quanfeng He, Zhibo Zhang, Tao Liang, Xue Ding, Yang Yang Li, Qing Wang,* Q.S. Zeng,* and Yong Yang*, Strong, Ductile, and Tough Nanocrystal-Assembled Freestanding Gold Nanosheets, Nano Lett., 22,822 (2022).

88. Hao Du, Yu Gong,* Yuantao Xu, Q.S. Zeng, Lianghua Xiong, Yu Li, Yihong Nie, Junfeng Wang, Xuejun Jin,* Obtaining Ultrastrong and Ductile Steel with Hierarchical Lamellar Duplex Phase Microstructure by Two-stage Martensitic Transformation Mechanism, Metall. Mater. Trans. A, 53, 1613–1629 (2022).

87. Liliang Shao; Lin Xue; Qiang Luo; Kuibo Yin; Zirui Yuan; Mingyun Zhu; Weiwei Zhu; Tao Liang; Q.S. Zeng, Litao Sun, and Bao-Long Shen,* Heterogeneous GdTbDyCoAl high-entropy alloy with distinctive magnetocaloric effect induced by hydrogenation, J. Mater. Sci. Tech.,109, 147-156 (2022).

86. Siyi Di, Qianqian Wang, Yiyuan Yang, Tao Liang, Jing Zhou, Lin Su, Kuibo Yin, Q.S. Zeng, Litao Sun, and Baolong Shen*, Efficient rejuvenation of heterogeneous {[(Fe0.5Co0.5)0.75B0.2Si0.05]96Nb4}99.9Cu0.1 bulk metallic glass upon cryogenic cycling treatment, J. Mater. Sci. Tech., 97, 20 (2022).

85. Qiang Luo, Donghui Li, Mingjuan Cai, Siyi Di, Zhengguo Zhang, Q.S. Zeng, Qianqian Wang, and Bao-Long Shen,* Excellent magnetic softness-magnetization synergy and suppressed defect activation in soft magnetic amorphous alloys by magnetic field annealing, J. Mater. Sci. Tech., 116, 72-78 (2022).

84. Changxin Chen,* Yu Lin, Wu Zhou, Ming Gong, Justin Zachary Wu, Jian Nong Wang, Fan Yang, Kai Tak Lam, Q.S. Zeng, Wenpei Gao, Jian-min Zuo, Jie Liu, Guosong Hong, Alexander L. Antaris, Meng-Chang Lin, Jing Guo, Wendy L. Mao,* Hongjie Dai,* Sub-10-nm graphene nanoribbons with atomically smooth edges from squashed carbon nanotubes, Nat. Electron., 4, 653 (2021).

83. Zhi Chen,† Zhaoyue Sun,† Fujun, Lan, Xin Zhang, Ziliang Yin, Ye Liu, Zhidan Zeng, Yang Ren, Hongbo Lou,* Baolong Shen, Q.S. Zeng,* Quantifying a partial polyamorphic transition in a Ce-based metallic glass during cooling, J. Appl. Phys., 130, 145901 (2021).

82. Yue Tang, Qiang Zhang, Hongbo Lou, Lijie Tan, Shixue Guan, Mengyang Huang, Wenqiang Wang, Q.S. Zeng, Duanwei He, Fang Peng*, Elucidating the Structural properties and Unusual Grain Rotation Behavior of GdB6 under High Pressure, J. Alloys Compd., 886, 161239 (2021).

81. Qing Yu, Jingyang Zhang, Tianyu Wang, Minhyuk Park, Hongliang Dong, Songyi Chen, Xin Zhang, Songhao Guo, Yangyang Li, Q.S. Zeng,* and Yong Yang*, Transformation of Freestanding Carbon-Containing Gold Nanosheets into Au Nanoparticles Encapsulated within Amorphous Carbon: Implications for Surface Modification of Complex-Shaped Materials and Structures, ACS Appl. Nano Mater., 4, 5, 5098 (2021).

80. Yinran Lin, Zhenhai Yang*, Zunke Liu, Jingming Zheng, Mengmeng Feng, Yuyan Zhi, Linna Lu, Mingdun Liao, Wei Liu, Dian Ma, Qingling Han, Hao Cheng, Q.S. Zeng, Zhizhong Yuan, Baojie Yan, Yuheng Zeng*, Jichun Ye*, Dual-Functional Carbon-Doped Polysilicon Films for Passivating Contact Solar Cells: Regulating Physical Contacts while Promoting Photoelectrical Properties, Energy Environ. Sci., 14, 6406-6418 (2021).

79. Hao Du, Yu Gong,* Q.S. Zeng, Yu Li, Na Min, Xuejun Jin,* Interpretation of Dynamic Strain Aging in an Intercritical Annealed Steel by Dislocation Multiplication Induced by Martensitic Transformation, Metall. Mater. Trans. A, 52, 5258–5273 (2021).

78. Mingjuan Cai, Qiang Luo, Q.S. Zeng, Baolong Shen,* Combined effect of demagnetization field and magnetic anisotropy on magnetocaloric behavior and magnetocaloric-magnetoresistance correlation in GdTmErCoAl high-entropy amorphous alloy, J. Magn. Magn. Mater., 528, 167817 (2021).

77. Liliang Shao; Qianqian Wang; Lin Xue; Mingyun Zhu; Anding Wang; Junhua Luan; Kuibo Yin; Qiang Luo; Q.S. Zeng, Litao Sun, Baolong Shen, Effects of minor Si addition on structural heterogeneity and glass formation of GdDyErCoAl high-entropy bulk metallic glass, J. Mater. Sci. Tech., 11, 378 (2021).

76. Jing Zhou, Si-Yi Di, Bao-An Sun, Rui Zhao, Q.S. Zeng,, Jian-Guo Wang, Zhen-Zhong Sun, Wei-Hua Wang, and Bao-Long Shen,* Pronounced β-relaxation in plastic FeNi-based bulk metallic glasses and its structural origin, Intermetallics, 136, 107234 (2021).

75. Jing Zhou, Siyi Di, Baoan Sun, Q.S. Zeng, Baolong Shen, Correlation between deformation behavior and atomic-scale heterogeneity in Fe-based bulk metallic glasses, J. Mater. Sci. Tech., 65, 54 (2021).

74. Jing Zhou, Qianqian Wang, Q.S. Zeng, Kuibo Yin, Anding Wang, Junhua Luan, Litao Sun and Baolong Shen, A plastic FeNi-based bulk metallic glass and its deformation behavior, J. Mater. Sci. Tech., 76, 20 (2021).

73. Tao Liang, Fei Zhang, Xin Zhang, Xiehang Chen, Songyi Chen, Hongbo Lou, Zhidan Zeng, Dazhe Xu, Ke Yang, Yuming Xiao, Paul Chow, Baolong Sheng, Q.S. Zeng,* Pressure-induced spin transition in a Fe78Si9B13 metallic glass, J. Appl. Phys., 129, 165901 (2021).

72. Xiehang Chen, Hongbo Lou, Zhidan Zeng, Benyuan Cheng, Xin Zhang, Ye Liu, Dazhe Xu, Ke Yang, Q.S. Zeng,* Structural transitions of 4:1 methanol-ethanol mixture and silicone oil under high pressure, MRE, 6, 038402 (2021).

71. Ziliang Yin, Hongbo Lou,* Hongwei Sheng, Zhidan Zeng, Wendy L. Mao, Q.S. Zeng,* Polyamorphism in a solute-lean Al-Ce metallic glass, J. Appl. Phys., 129, 025108 (2021).

70. Q.S. Zeng,* Ziliang Yin, Hongbo Lou,* Polyamorphic transitions in metallic glasses, Acta Metall. Sin., 57, 491 (2021).

69. Ye Liu, Hongbo Lou, Fei Zhang, Tao Liang, Songyi Chen, Shubin Li, Xin Zhang, Lijie Tan, Vitali B. Prakapenka, Eran Greenberg, Yanping Yang, Zhidan Zeng, Q.S. Zeng,* Pressure-induced crystallization of an amorphous martensite alloy, J. Appl. Phys., 128, 085901 (2020).

68. Benyuan Cheng, Hongbo Lou, Abhishek Sarkar, Zhidan Zeng, Fei Zhang, Xiehang Chen, Lijie Tan, Konstantin Glazyrin, Hanns-Peter liermann, Jinyuan Yan, Liang Wang, Ruzica Djenadic, Horst Hahn, Q.S. Zeng,* Lattice distortion and stability of (Co0.2Cu0.2Mg0.2Ni0.2Zn0.2)O high-entropy oxide under high pressure, Mater. Today Adv., 8, 100102 (2020).

67. Zhidan Zeng*, Q.S. Zeng, Mingyuan Ge, Bin Chen, Hongbo Lou, Xiehang Chen, Jinyuan Yan, Wenge Yang, Deren Yang, Ho-kwang Mao, Wendy L. Mao, Origin of dramatic plasticity in nanostructured silicon, Phys. Rev. Lett. 124, 185701 (2020).

66. Qing Du, Xiongjun Liu, Huiyang Fan, Qiaoshi Zeng, Yuan Wu, Hui Wang, Debaditya Chatterjee, Yang Ren, Yubin Ke, Paul M. Voyles, Zhaoping Lu, Evan Ma, Reentrant glass transition leading to ultrastable metallic glass, Mater. Today, 34, 66 (2020).

65. Hongbo Lou, Zhidan Zeng, Fei Zhang, Songyi Chen, Peng Luo, Xiehang Chen, Yang Ren, Vitali B. Prakapenka, Clemens Prescher, Xiaobing Zuo, Tao Li, Jianguo Wen, Weihua Wang, Hongwei Shen, Qiaoshi Zeng,* Two-way tuning of structural order in metallic glasses, Nat. Commun., 11, 314 (2020).

64. Lijie Tan, Hongwei Sheng, Hongbo Lou, Benyuan Cheng, Yuanyuan Xuan, Vitali B. Prakapenka, Eran Greenberg, Q.S. Zeng, Fang Peng, Zhidan Zeng,* Bulk tetrahedral amorphous carbon synthesized by compressing glassy carbon at room temperature, J. Phys. Chem. C, 124, 5489, (2020).

63. Shubin Li, Fujun Lan, Songyi Chen, Di Peng, Yuankan Fang, Ren-Shu Wang, Hongbo Lou, Xin Zhang, Zhidan Zeng, Xiao-Jia Chen, Dong Qian, Q.S. Zeng,* Bulk intrinsic heterogeneity of metallic glasses probed by Meissner effect, Intermetallics, 119, 106721 (2020).

62. Hao Du, Yu Gong, Yu Li, Yuantao Xu, Xianwen Lu, Tao Liang, Q.S. Zeng, Xuejun Jin, Enhancement of Impact Toughness via Tailoring Deformation Compatibility of Constituent phases in Duplex Q&P steel with Excellent Strength and Ductility, Metall. Mater. Trans. A, 51, 2097 (2020).

61. Siyi Di, Qianqian Wang, Jing Zhou, Yiyang Shen, Jiaqi, Li, Mingyun Zhu, Kuibo Yin, Q.S. Zeng, Litao Sun, Baolong Shen, Scripta Mater., 187, 13 (2020).

60. Jing Zhou, Qianqian Wang, Xidong Hui, Q.S. Zeng, Yuwei Xiong, Kuibo Yin, Baoan Sun, Litao Sun, Mihai Stoica, Weihua Wang, Baolong Shen, A novel FeNi-based bulk metallic glass with high notch toughness over 70 MPa m1/2 combined with excellent soft magnetic properties, Mater. Design, 191, 108597 (2020).

59. Fang Miao, Qianqian Wang, Q.S. Zeng, Long Hou, Tao Liang, Zhiqiang Cui, Baolong Shen, Excellent reusability of FeBC amorphous ribbons induced by progressive formation of through-pore structure during acid orange 7 degradation, J. Mater. Sci. Tech., 38, 107 (2020).

58. Qianqian Wang, Jing Zhou, Q.S. Zeng, Genlei Zhang, Kuibo Yin, Tao Liang, Weiming Yang, Mihai Stoica, Litao Sun, Baolong Shen, Ductile Co-based bulk metallic glass with superhigh strength and excellent soft magnetic properties induced by modulation of structural heterogeneity, Materialia, 9, 100561 (2020).

57. Ruilian Tang, Jiuhua Chen*, Q.S. Zeng, Yan Li, Xue Liang, Bin Yang, Yu Wang, Study of High-pressure Behavior of Goethite up to 32 GPa using X-ray Diffraction, Raman and Electrical Impedance Spectroscopy, Minerals, 10, 99 (2020).

56. Benyuan Cheng, Hongbo Lou, Abhishek Sarkar, Zhidan Zeng, Fei Zhang, Xiehang Chen, Lijie Tan, Vitali Prakapenka, Eran Greenberg, Jianguo Wen, Ruzica Djenadic, Horst Hahn, Qiaoshi Zeng,* Pressure induced tuning of lattice distortion in a high-entropy oxide, Commun. Chem., 2, 114 (2019).

55. Zhidan Zeng,*, Liuxiang Yang, Lijie Tan, Hongbo Lou, Vitali Prakapenka, Q.S. Zeng, Pressure-induced significant structure and electrical property change in glassy carbon at room temperature, Phys. Rev. Mater., 3, 033608 (2019).

54. Bangmin Zhang,+ Qiaoshi Zeng,+ Ronghui Kou, Liuxiang Yang, Hongbo Lou, Steve M. Heald, Jingsheng Chen, Yang Ding, Cheng-Jun Sun, and Gan Moog Chow, Evolution of non-local screening in K edge XANES for Pr0.67Sr0.33MnO3 under high pressure, J. Alloys Compd., 792, 108 (2019).( + equal contribution authors)

53. Lijie Tan, Zhidan Zeng,* Hongbo Lou, Fei Zhang, Xiehang Chen, Songyi Chen, Yuanyuan Xuan, Fang Peng,* Q.S. Zeng, Stability of zirconium carbide under high pressure and high temperature, J. Phys. Chem. C, 123, 10051 (2019).

52. Qing Du, Xiongjun Liu,* Q.S. Zeng, Hui Wang, Yuan Wu, Shi-Wei Chen, Zhao-Ping Lu,* A unique polyamorphic transition in a transition metal-based metallic glass under high pressure, Phys. Rev. B, 99, 014208 (2019).

51. Fei Zhang, Hongbo Lou, Benyuan Cheng, Q.S. Zeng,* High-pressure induced phase transitions in high-entropy alloys:A Review, Entropy, 21, 239 (2019).

50. Liang Wang, Fei Zhang, Zhihua Nie, Lu Wang, Fuchi Wang, Benpeng Wang, Shangcheng Zhou, Yunfei Xue,* Benyuan Cheng, Hongbo Lou, Xiehang Chen, Yang Ren, Dennis E. Brown, Vitali Prakapenka, Eran Greenberg, Zhidan Zeng, Q.S.Zeng,* Abundant polymorphic transitions in the Al0.6CoCrFeNi high-entropy alloy, Mater. Today Phys.,8, 1 (2019).

49. Benyuan Cheng, Fei Zhang, Hongbo Lou, Xiehang Chen, Peter K. Liaw, * Jinyuan Yan, Zhidan Zeng, Yang Ding, Q.S.Zeng,* Pressure-induced phase transition in the AlCoCrFeNi high-entropy alloy, Scripta Mater. 161, 88 (2019).

48. Qing Du, Xiongjun Liu,* Q.S. Zeng, Hui Wang, Yuan Wu, Shi-Wei Chen, Zhao-Ping Lu,* A unique polyamorphic transition in a transition metal-based metallic glass under high pressure, Phys. Rev. B, 99, 014208 (2019).

47. Fei Zhang, Hongbo Lou, Songyi Chen, Xiehang Chen, Zhidan Zeng, Jinyuan Yan, WuxinZhao, Yuan Wu, Zhaoping Lu, Q.S.Zeng,*, Effects ofnon-hydrostaticity and grain size on the pressure-induced phase transition ofthe CoCrFeMnNi high-entropy alloy, J. Appl. Phys., 124, 115901 (2018).

46. Zhifeng Lei, Xiongjun Liu, Yuan Wu, Hui Wang, Suihe Jiang, Shudao Wang, Xidong Hui, Yidong Wu, Baptiste Gault, Paraskevas Kontis, Dierk Raabe, Lin Gu, Qinghua Zhang, Houwen Chen, Hongtao Wang, Jiabin Liu, Ke An, Q.S. Zeng, Tai-gang Nieh, Zhaoping Lu, Enhanced strength and ductility in a high-entropyalloy via ordered oxygen complexes, Nature, 563, 546 (2018).

45. Muwei Ji, Hongzhi Wang, Yu Gong, Haixia Cheng, Lirong Zheng, Xinyuan Li, Liu Huang, Jia Liu, Zhihua Nie, Q.S. Zeng, Meng Xu, Jiajia Liu, Xiaoxu Wang, Ping Qian, Caizhen Zhu, Jin Wang, Xiaodong Li, and Jiatao Zhang,High Pressure Induced in Situ Solid-State Phase Transformation of Nonepitaxial Grown Metal@Semiconductor Nanocrystals,J. Phys. Chem. Lett., 9, 6544 (2018).

44. Qianqian Wang, Lu Yuan, Mingxiu Chen, Dandan, Xu, Zhiqiang Cui; Q.S. Zeng, Pinghua Lin, Chenglin Chu; Baolong Shen, Competitive effect of structural heterogeneity and surface chemical states on catalytic efficiency of FeSiBPCu amorphous and nanocrystalline alloys, ACS Appl. Nano Mater., 2,214 (2018).

43. Q.S. Zeng,* Zhidan Zeng, Hongbo Lou, Yoshio Kono, Bo Zhang, Curtis Kenney-Benson,Changyong Park, Wendy L. Mao, Pressure-induced elastic anomaly in apolyamorphous metallic glass, Appl.Phys. Lett.,110, 221902 (2017).

42. Zhidan Zeng, Liuxiang Yang, Q.S. Zeng*,Hongbo Lou, Hongwei Sheng, Jianguo Wen*, Dean J. Miller, Yue Meng, Wenge Yang,Wendy L. Mao and Ho-kwang Mao* Synthesisof glassy diamond, Nat. Commun., 8, 322, (2017).

41. Fei Zhang, Yuan Wu, Hongbo Lou, Zhidan Zeng, Vitali Prakapenka, Eran Greenberg,Yang Ren, Jinyuan Yan, John S. Okasinski, Xiaongjun Liu, Yong Liu, Q.S. Zeng,* Zhaoping Lu,* Polymorphism in a high-entropy alloy, Nat. Commun., 8, 15687 (2017).

40. XueLiang, Jiuhua Chen, Maria Teresa Mora, Jose Fernandez Urdaneta, Q.S.Zeng, Effect of Precipitation on the Hardness ofTernary Metallic Glass, Advances in Materials Physics and Chemistry,7, 255-262. (2017).

39. L.Yang, H.Y. Li , P.W. Wang , S.Y. Wu , G.Q. Guo , B. Liao, Q.L. Guo, X.Q. Fan ,P. Huang, H.B. Lou , F.M. Guo , Q.S.Zeng , T. Sun , Y. Ren , and L.Y. Chen,Structuralresponses of metallic glasses under neutron radiation, Sci. Rep. 7,16739 (2017).

38. JianDai, Y. G. Wang, Liang Yang, Gongting Xia, Q.S.Zeng, and Hongbo Lou., Structuralaspects of magnetic softening in Fe-based metallic glass during annealing, Scripta Mater., 127, 88 (2017).

37. Jian Dai, Y. G. Wang, Liang Yang, Gongting Xia, Q.S.Zeng, and Hongbo Lou., Thermaldependence of structural and magnetic properties in an amorphous Fe-Si-B-Cualloy, J.Alloys Compd., 695 1266 (2017).

36. Q.S. Zeng,* Yu Lin,Yijin Liu, Zhidan Zeng, Crystal Y. Shi, Bo Zhang, Hongbo Lou, Stanislav V.Sinogeikin, Yoshio Kono, Curtis Kenney-Benson, Changyong Park, Wenge Yang,Weihua Wang, Hongwei Sheng, Ho-kwang Mao, Wendy L. Mao,General 2.5 Power Law of Metallic Glasses, PNAS, 113, 1714 (2016).

(Highlightslink:https://www.sciencedaily.com/releases/2016/02/160208213843.htm )

35. Lingrui Wang, Kai Wang, Guanjun Xiao, Q.S.Zeng, and Bo Zou, PressureInduced Structural Evolution and Band Gap Shifts of Organometal Halide Perovskite-BasedMethylammonium Lead Chloride, J.Phys. Chem. Lett., 7, 5273 (2016).

34. BinChen, Jung-Fu Lin, Jiuhua Chen, Hengzhong Zhang, and Q.S. Zeng, Synchrotron-basedhigh-pressure research in materials science,MRS Bulletin, 41 437 (2016).

33. Zhidan Zeng, Nian Liu, Q.S. Zeng,Seok Woo Lee, Wendy L. Mao, and Yi Cui, Insitu measurement of lithiation-induced stress in silicon nanoparticles usingmicro-Raman spectroscopy, NanoEnergy, 22, 105 (2016).

32. Rachel Liontas, Mehdi J. Zadeh, Q.S. Zeng,Yong-Wei Zhang, Wendy L. Mao, Julia R. Greer, Substantial tensile ductility in sputtered Zr-Ni-Al nano-sized metallicglasses, Acta Materialia, 118,270 (2016).

31. Guqing Guo, Liang Yang, Shiyang Wu, Q.S.Zeng,* Chengjun Sun, YingangWang, Structure-induced microalloyingeffect in multicomponent alloys, Materials& Design, 103, 308 (2016).

30. D.Z.Chen, C.Y. Shi, Q. An, Q.S. Zeng,W.L. Mao, W.A. Goddard, III, J.R. Greer, Fractalatomic-level percolation in metallic glasses, Science, 349 1306 (2015).

29. Zhidan Zeng, Qingfeng Zeng, Nian Liu, Artem R. Oganov, Q.S. Zeng, Yi Cui, and Wendy L. Mao, A Novel Phase of Li15Si4 Synthesized underPressure, Adv. Energy Mater., 5,1500214 (2015).

28. Zhao Zhao, Q.S. Zeng, HaijunZhang, Shibing Wang, Shigeto Hirai, Zhidan Zeng, Wendy. L. Mao, Structural transition and amorphization incompressed alpha-Sb2O3, Phys. Rev. B, 91, 184112 (2015).

27. Zhao Zhao, Haijun Zhang, Hongtao Yuan, Shibing Wang, Yu Lin, Q.S.Zeng, GangXu, Zhenxian Liu, Gunvant. K. Solanki, Kirit D. Patel, Yi Cui, Harold Y. Hwang,Wendy L. Mao,Pressure induced metallization with absenceof structural transition in layered MoSe2, Nat. Commun. 6:7312|DOI: 10.1038/ncomms8312 (2015).

26. Zhihua Nie, Yandong Wang, Shunli Shang, Q.S.Zeng, Yang Ren, Dongmei Liu, Wenge Yang, Yi Wang, and Zi-Kui Liu, Strain-induced dimensionality crossover ofprecursor modulations in Ni2MnGa, Appl. Phys. Lett., 106, 021910 (2015).

25. Q.S. Zeng,* Y. Kono, Y. Lin,Z.D. Zeng, J.Y. Wang, S. V. Sinogeiking, C. Park, Y. Meng, W. Yang, H.K. Mao, W.L. Mao, Universal FractionalNoncubic Power law for Density of MetallicGlasses, Phys. Rev. Lett., 112, 185502 (2014).

24. Yang Ding, Cheng-Chien Chen, Q.S. Zeng,Heung-Sik Kim, Myung Joon Han, Mali Balasubramanian, Robert Gordon, Fangfei Li,Ligang Bai, Dimitry Popov, Steve M. Heald, Thomas Gog, Ho-kwang Mao, and Michelvan Veenendaal, Novel Pressure-InducedMonoclinic Metallic Phase of V2O3, Phys. Rev. Lett., 112, 056401 (2014).

23. Li Zhang, Yue Meng, Wenge Yang, Lin Wang, Wendy L. Mao, Q.S. Zeng, Jong Seok Jeong, Andrew J. Wagner, K. AndreMkhoyan, Wenjun Liu, Ruqing Xu, and Ho-kwang Mao, Disproportionation of (Mg,Fe)SiO3 perovskite in Earth’s deeplower mantle, Science, 344, 877(2014).

22. Z. Zeng, Q.S. Zeng, W. L. Mao,S. X. Qu, Phase transitions inindentation induced metastable phases of silicon,J. Appl. Phys., 115,103514 (2014).

21. Zhao Zhao, Shibing Wang, Tongfei Qi, Q.S.Zeng, Shigeto Hirai, P. P. Kong, L. Li, C. Park, S.J. Yuan, ChangqingJin, G. Cao, Wendy Mao, Pressure inducedsecond-order structural transition in Sr3Ir2O7, J. Phys.: Condens. Matter., 26, 215402(2014).

20. Q.S. Zeng,* Wendy L. Mao, Hongwei Sheng, Zhidan Zeng, QingyangHu, Yue Meng, Hongbo Lou, Fang Peng, Wenge Yang, Stanislav. V. Sinogeikin andJian-Zhong Jiang, The Effect ofComposition on Pressure-Induced Devitrification in Metallic Glass, Appl. Phys. Lett. 102, 171905 (2013).

19. Yu Lin, Q.S. Zeng, Wenge Yang,Wendy L. Mao, Pressure-induced densificationin GeO2 glass: A transmission x-ray microscopy study, Appl. Phys. Lett., 103 (26), 261909 (2013).

18. Z. Zeng, N. Liu, Q.S. Zeng, Y.Ding, S. X. Qu, Y. Cui, W. L. Mao, Elasticmoduli of polycrystalline Li15Si4 produced in lithium ionbatteries, J. Power Sources,242, 732 (2013).

17. L. Yang, G.Q. Guo, L.Y. Chen, C.L. Huang, T. Ge, D. Chen, P.K. Liaw, K. Saksl, Y.Ren, Q.S. Zeng, B. LaQua, F.G. Chen, and J.Z. Jiang, Atomic-scalemechanisms of the glass-forming ability in metallic glasses, Phys. Rev. Lett., 109, 105502 (2012).

16. H.B.Lou, Y.K. Fang, Q.S. Zeng,Y.H. Lu, X.D. Wang, Q.P. Cao, K. Yang, X.H. Yu, L. Zheng, Y.D. Zhao, W.S. Chu, T.D.Hu, Z.Y. Wu, R. Ahuja and J.Z. Jiang, Pressure-inducedamorphous-to-amorphous configuration change in Ca-Al metallic glasses, Sci. Rep. 2, 376 (2012).

15. Q.S.Zeng, Hongwei Sheng, Yang Ding, Lin Wang,Wenge Yang, Jian-Zhong Jiang,Wendy L.Mao, and Ho-Kwang Mao, Long-RangeTopological Order in Metallic Glass, Science,332, 1404 (2011).

(Highlightslink:http://www.sciencedaily.com/releases/2011/06/110616142724.htm )

14. Q.S. Zeng,* C.R. Rotundu, W. L. Mao, J.H. Dai, Y.M. Xiao, P.Chow, H.-k. Mao, X.J. Chen, C. L. Qin and J.Z. Jiang,Low temperature transportproperties of Ce-Al metallic glasses, J. Appl.Phys. 109, 113716 (2011) .

13. W.Liu, Q.S. Zeng, Q.K. Jiang, L.P.Wang, and B.S. Li, Density and elasticityof Zr46Cu37.6Ag8.4Al8 bulk metallicglass at high pressure, ScriptaMater. 65, 497, (2011).

12. Q.S. Zeng, Y. Ding, W.L. Mao, W. Yang, J. Shu, S. V. Sinogeikin, H.-k. Mao, and J.Z. Jiang, Origin of Pressure-Induced Polyamorphism in Ce75Al25Metallic Glass,Phys. Rev. Lett., 104,105702 (2010).

(Highlightslink:http://www.sciencedaily.com/releases/2010/03/100316142525.htm )

11. Q.S. Zeng,* V.V. Struzhkin, Y.Z.Fang, C.X. Gao, H.B. Lou, X.D. Wang, C. Lathe, W. L. Mao, F.M. Wu, H.-K. Mao,and J.Z. Jiang, Properties of Polyamorphous Ce75Al25Metallic Glasses, Phys. Rev. B 82,054111 (2010).

10. Q.S. Zeng,* Y.Z. Fang, H.B. Lou,Y. Gong, X.D.Wang, K.Yang, A.G. Li, S. Yan, C. Lathe, F.M. Wu, X.H. Yu and J.Z.Jiang, Low-density to high-density transitionin Ce75Al23Si2 metallic glass, J. Phys.: Condens. Matter. 22, 375404(2010).

9. Q.S. Zeng, Y. Ding, W.L. Mao, W. Luo, A. Blomqvist, R. Ahuja, W. Yang, J. Shu, S.V.Sinogeikin, Y. Meng, D. Brewe, J. Z. Jiang, and H.-k. Mao, Substitutionalalloy of Ce and Al, PNAS, 106, 2515 (2009). (Selectedas the Cover Highlights by PNAS)

(Highlightslink:http://www.sciencedaily.com/releases/2009/02/090226082515.htm )

8. X.D. Wang, Q.S. Zeng, J.Z. Jiang, Applicationsof synchrotron radiation-based techniques in studying the structure andproperties of disordered alloys, Physics(China, in Chinese), 38, 489 (2009).

7. L. Jia, J. R. Sun, F. W. Wang, T. Y Zhao, H. W. Zhang,B. G. Shen, D. X. Li, S. Nimori, Y. Ren,Q.S.Zeng,Volume dependence of the magnetic coupling in LaFe13-xSixbased compounds, Appl. Phys. Lett.92, 101904 (2008).

6. Q.S. Zeng,Y.C. Li, C.M. Feng, P. Liermann, M. Somayazulu, G.Y. Shen, H.-k.Mao, R. Yang, J. Liu, T.D. Hu, and J.Z. Jiang, Anomalouscompression behavior in LaCe-based metallic glass under high pressure, PNAS, 104,13565 (2007).

(Highlightslink:http://www.sciencedirect.com/science/article/pii/S1369702107702298)

5. Q.S. Zeng, J.F. Liu, G.Q. Zhang, L.N. Wang and J.Z. Jiang, Synthesis of LaCe-based bulk metallic glasses with low glasstransition temperature, Intermetallics, 15, 753 (2007).

4. C.W.Yao, Q.S. Zeng, G. F. Goya, T. Torres, J.F. Liu, H.P. Wu, M.Y.Ge, Y.W. Zeng, and J.Z. Jiang, Monodisperse ZnFe2O4Nanocrystals: Synthesis and Magnetic Properties, J. Phys. Chem. C, 111, 12274 (2007).

3. K. Saksl, P. Jóvári, H. Franz, Q.S. Zeng, J.F. Liu, J.Z. Jiang, Atomicstructure of Al89La6Ni5 metallic glass, J. Phys.: Condens. Matter 18, 7579 (2006).

2. G.Q. Zhang, F.J. Liu, Q.S. Zeng, L.N. Wang, Q.J. Liu, J.Z. Jiang, Effectof Nb in (La0.5Ce0.5)64-xAl16Ni5Cu15Nbx(x=0-5)bulk metallic glasses, Trans.Nonferrous Met. Soc. China 16, 131 (2006).

1. Q.K. Jiang, G.Q. Zhang, L.Y. Chen, Q.S. Zeng, J.Z. Jiang, Centimeter-Sized (La0.5Ce0.5)-basedBulk Metallic Glasses,J. Alloys Compd. 242, 179(2006).

Qiaoshi Zeng was at the "mission peak" in Bay area, California.

Qiaoshi Zeng, Hongbo Lou and Fei Zhang were doing experiment at 13-IDC, APS, Chicago

Qiaoshi Zeng and Hongbo Louwere doing experiment at 16-IDB, APS, Chicago

Qiaoshi Zeng, Hongbo Lou and Fei Zhang were doing experiment at 12.2.2, ALS, Berkeley

Zhidan Zeng, Hongbo Lou and Fei Zhang were doing experiment at 13-IDC, APS, Chicago

Zhidan Zeng was doing experiments at beamline 1-ID, APS, Chicago

Zhidan Zeng was loading high pressure sample at beamline 13-IDC, APS,Chicago

Fei Zhang was doing experiments at beamline 1-ID, APS

Fei Zhang at beamline 1-ID-E, APS

Hongbo Lou at beamline 1-ID-E, APS

Hongbo Lou was doing experiments at beamline 11-IDC, APS

Songyi Chen was doing in situ high pressure laser heating XRD at beamline 12.2.2, ALS.

Xin Zhang, Hongbo Lou and Zhidan Zeng were doing experiment at the 12-IDB, APS.

Explore Around

The biggest species on earth——sequoia. "Lou, Zeng, Fei"

Group field trip at Yosemite.

Challenging the limit. "会当凌绝顶" ---Hongbo Lou

Challenging the limit. "会当凌绝顶"---Fei Zhang

“会当击水三千里”--Hongbo Lou under the Niagara fall

Songyi Chen was hiking at Lake Tahoe

We are looking for highly self-motivated graduate student (Master and PhD) and postdoc candidates to join our AMAT group at Shanghai lab of HPSTAR.

The applicants with background in Materials Science, Physics, Chemistry and expertise in synchrotron radiation x-ray, neutron and high pressure techniques are preferred.

Stipend: For postdocs, the specific annual salary depends on each candidate's experience, background, and interview performance which is 280,000 to 570,000 RMB (41,000 to 87,000 US dollars).

And the standard annual stipend is above 57,600-69,600 RMB for master students and above 81,600-99,600 RMB for PhD students depending on the grade (duration studied at HPSTAR), plus three major scholarships from HPSTAR and Graduate school up to 33,000 RMB.

HPSTAR also will provide strong financial support for performing overseas experiments and attending conferences.

All the positions are open now. If you are interested, please send Dr. Zeng ( zengqs@hpstar.ac.cn ) your CV, a research plan and the contact information of three references.

常年欢迎对非晶态材料和物理感兴趣的硕士,博士,博士后加盟!

l 热爱材料科学前沿研究和自由探索?

l 想得到严格、系统、国际化的科研训练 ?

l 想常常能和保持在科研一线工作的国际顶尖科学家交流,获得直接的指导?

l 想在世界一流的实验平台上开始自己的研究生涯?

l 想不用考TOFEL, GRE也能“自由出入”去世界顶级机构开展尖端科学研究?

l 想发篇Science、Nature博士毕业?

l 想毕业后被推荐到世界顶尖科研院所继续深造?

l 想给自己一个无悔的青春,一个充实的未来?

请联系我们,加入高压非晶态材料团队,给你的科学梦想插上翅膀!

Qiaoshi(Charles) Zeng

zengqs@hpstar.ac.cn

DON’T LIMIT YOUR CHALLENGES! CHALLENGE YOUR LIMITS!